Conveyor for Underground ApplicationsTransporting material safe and efficiently underground.

Customer requirements:

Underground mining makes high demands on material transport, such as limited space as well as the necessity to avoid exhaust emissions and heat development, to name only some.

Our solution:

The Doppelmayr conveyor for underground applications convinces through a maintenance-free conveying line, less moving parts and, consequently, high availability even in harsh operating conditions. It gives the chance to reduce the haul truck fleet and the exhaust emissions.

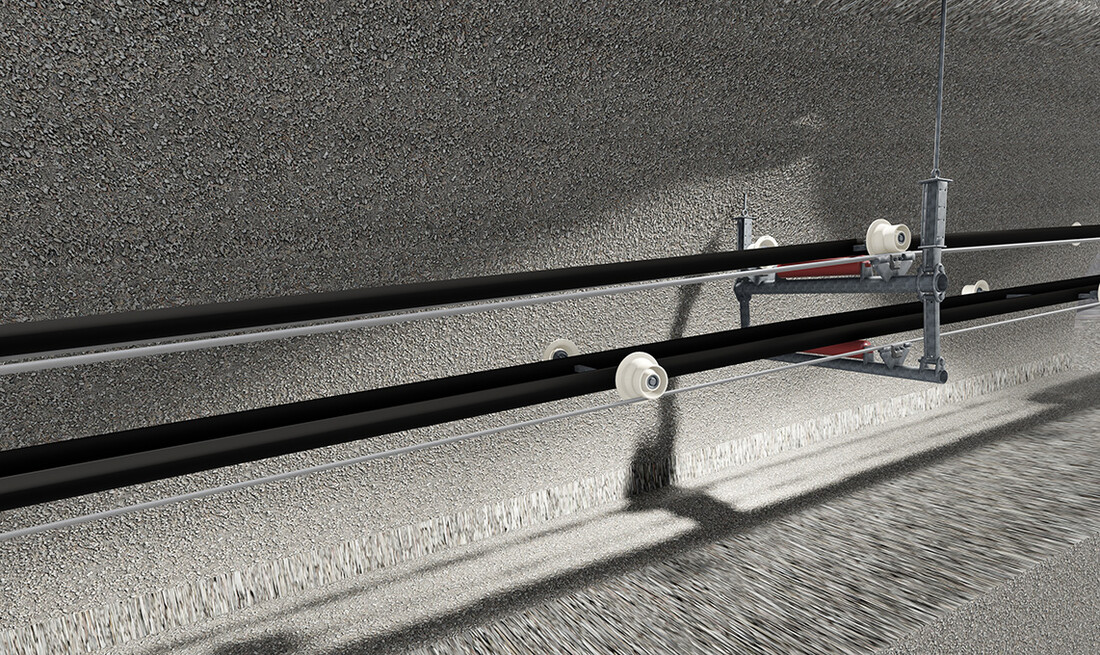

The novel concept adapts the proven RopeCon® system to the specific requirements of an underground application. The wheel sets run on track ropes and positively guide the belt. The track rope frames are suspended from the tunnel ceiling.

Maintenance is simple and cost effective, as all moving parts are mounted to the belt and will pass the terminals at regular intervals. The belt is turned after passing the unloading point. Thus the line is not soiled by any residual material falling from the returning belt.

| System | RopeCon® |

| Max. lump size | 150 - 400 mm |

| Difference in elevation (in one flight) | 750 m |

| Conveying capacity | 2,000 - 10,000* t/h |

| Clear shaft diameter required | from 3.5* m |

| *depending on material properties and operating conditions | |

| Max. inclination | Up to 30° without cleats |

| Up to 90° using cleats (Vertical conveyor) |